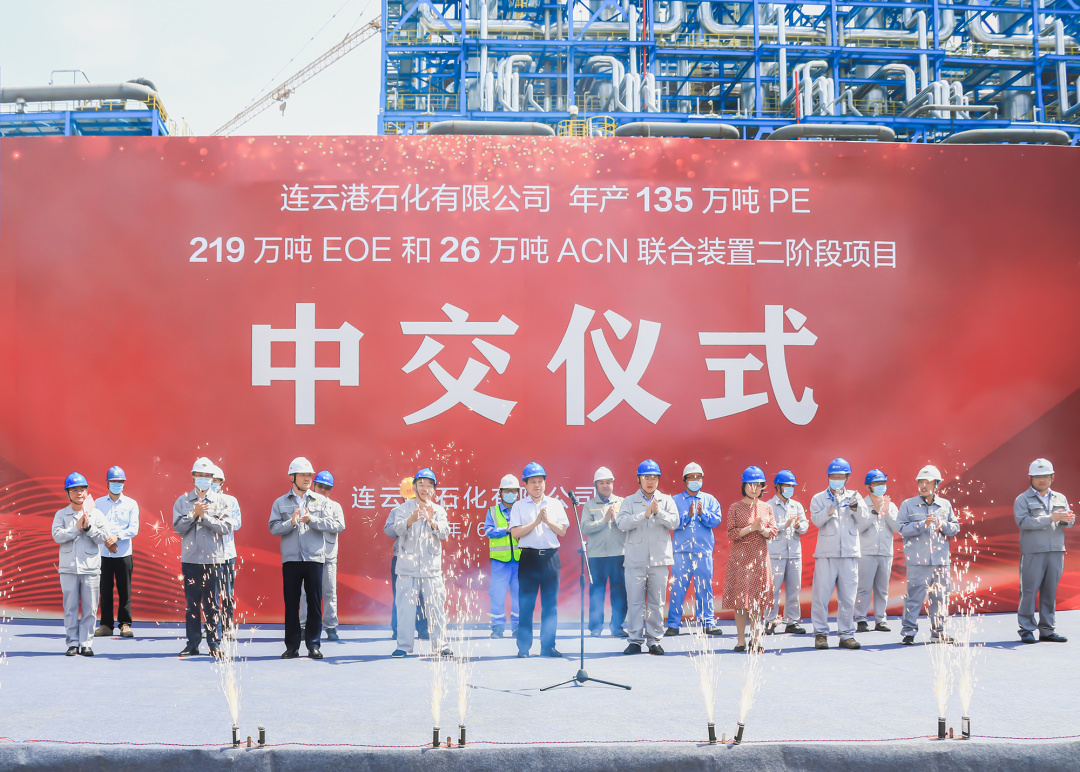

On Jun. 1st, the handover of phase II of STL Lianyungang Petrochemical 1.35m PE t/a, 2.19m EOE t/a and 260k ACN t/a Integrated Units was successful, marking the project’s transition from construction to trial operation. It further consolidated the light hydrocarbon integration industry layout of STL, ensure the downstream raw material supply, and drove the coordinated development of high value: added industrial chains such as new polymer material in the base, which would push Xuwei base to become a billion-dollar industrial park and to build a trillion-dollar petrochemical industry cluster.

As the biggest ethane comprehensive utilization project, STL’s Lianyungang Petrochemical Project with 33.5b RMB investment was one of the Major Projects in Jiangsu Province. Phase I was already put into operation in May, 2021. The handover units of phase II included 1.35m PE t/a, 0.73m EO t/a, 0.4m PE t/a, 0.6m Styrene t/a and other auxiliary devices, etc. phase II was expected to be in trial at the end of June. After full operation of both phase I and phase II, it would achieve over 30b RMB OI and over 10b RMB tax revenue every year. Besides, it would also drive products mutual supply in the park up by nearly 20b RMB, which formed circular economy in the park and laid the foundation of building an advanced, green low-carbon comprehensive utilization industrial base.

STL actively responded the national “Carbon Peak and Carbon Neutral” strategy and “the Fourteenth ‘Five-Year Plan’”, continuously improving in innovation, energy conservation and emission reduction, green and low-carbon, which promoted the high-quality development of the industry in all areas, the VP of STL and the GM of Lianyungang Base Mr. Zhu Xiaodong said.

As the major project to practice light hydrocarbon raw material and achieve transformation and upgrading, the project saved energy and reduced carbon emission from source, process and ending. It used light hydrocarbon source material and produced ethylene by ethane cracker. The comprehensive energy conservation was less than 50% of naphtha cracking, the reuse rate of wastewater after treatment was 95% and could recycle 0.3m t/a CO₂ which was the equivalent of planting 15m trees.

The project used advanced international technology, and created several domestic and global records. The officer of Xuwei New District stated that the handover of Lianyungang Petrochemical Phase II would reduce the dependence on foreign imports of ethylene significantly and achieve the supply of raw material of light hydrocarbon high-valued new material, which is significant in insuring the national energy safety, accelerating the green and low-carbon development of the petrochemical industry and promoting the transformation of our country from petrochemical big country to powerful country.